News

Contact Us

Address: 3,6,8/F, BLDG 3, No.7, LangFeng Road, Xinshi Community, Dalang, Longhua District, Shenzhen, China

Tel: +86 0755 2955 5011

E-mail: Info@fittop.com

News

How Can Our Manufacturer Assist You in Designing and Developing Masks That Meet Market Demands?

Tue Apr 30 10:56:21 CST 2024

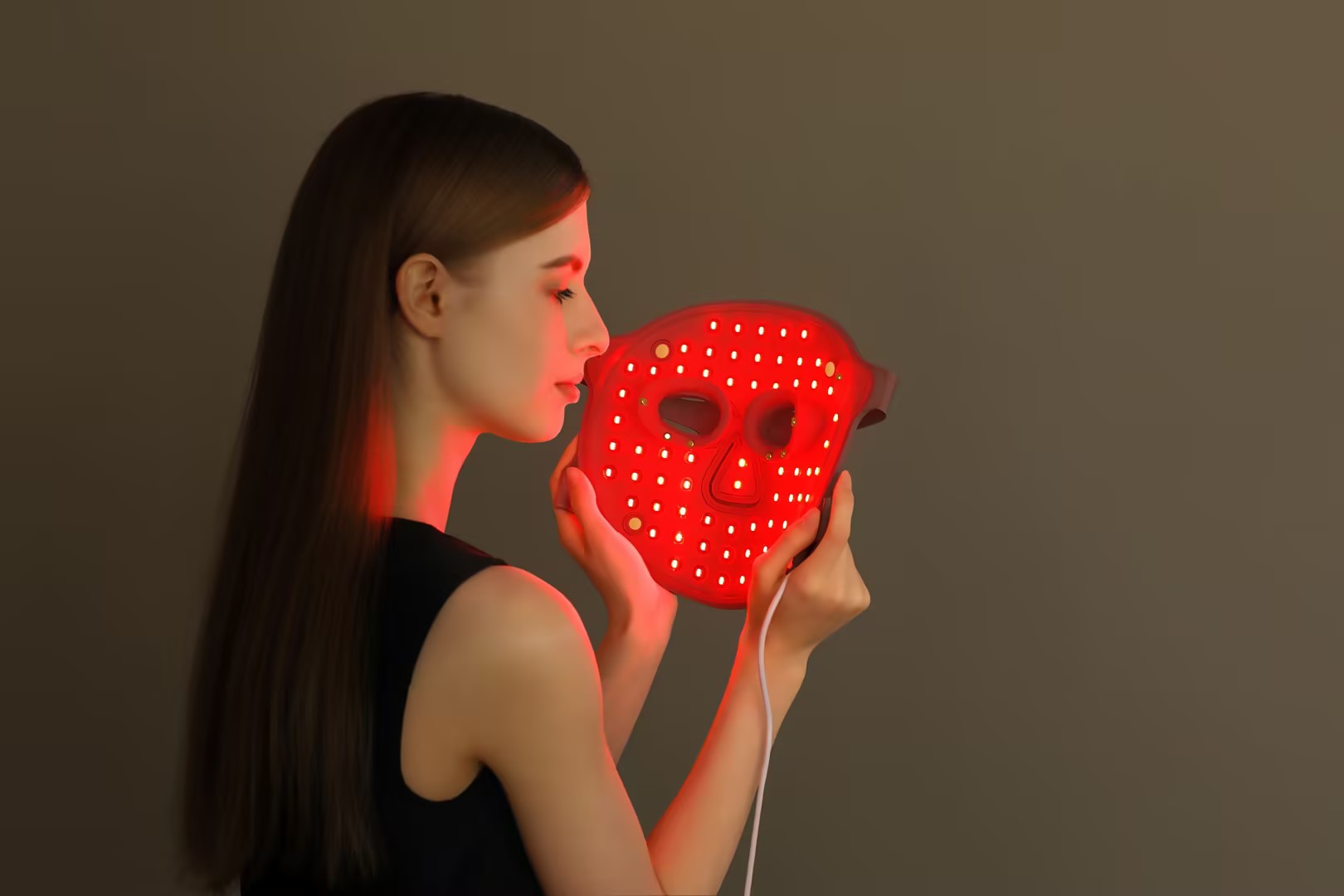

Custom LED masks are highly popular because they are a trending tool for reducing wrinkles and achieving youthful skin. They enable at-home anti-aging skincare routines. LED masks can help improve skin tone, reduce wrinkles, and boost collagen production. FITTOP offers comprehensive services for designing, manufacturing, and customizing LED masks.

In this article, we will introduce the production process of our LED masks and explain how as the original manufacturer, we can assist you in designing and developing masks that meet market demands.

Design and Development Process for LED Masks

People have different preferences and needs for LED masks. Our series of processes help you design LED masks that meet customer demands. Our LED mask manufacturing process starts with coordination among our teams: research and development, procurement, and production, to fulfill specific customer requirements for LED masks.

We take each customer seriously and assemble specialized project teams to visualize your design during the product design and development phases. The detailed process includes:

Product Design Planning

Researching the market prospects, sales models, cost control, process capabilities, and personnel input for LED masks by the research and development department, marketing center, and business department based on potential market demands. Cost calculations are then carried out, and once confirmed by the customer, we proceed to the product design phase.

Product Design Input

Product Functionality: Defining the expected functions and performance benchmarks of the product.

Product Appearance: Designing the color, pattern, material, and shape of the LED mask as per customer requirements.

Technical Requirements: Listing specific technical specifications and limitations that determine product design and engineering aspects, including dimensions, weight, and power.

Customer Requirements: Incorporating specific requests, preferences, and expectations of end-users or customers.

Product Design Output

Design outputs mainly include product standards, drawings, bill of materials (BOM), process flowcharts, operation manuals, quality control (QC) engineering drawings, instructions, and packaging.

Why Choose Us as Your Best Option for Custom LED Masks?

Professional Technical Support: We have an experienced team of research experts, engineers, and designers who can provide comprehensive support and consultation from concept to finished product.

Customized Services: We are committed to meeting the unique needs of customers. You can choose the color, pattern, material, and shape of LED masks, and we will design them according to your requirements.

Quality Control: We strictly adhere to international quality standards to ensure the stability and reliability of each LED mask's quality and performance.

Flexible Production Capacity: Whether you need small-batch customization or large-scale production, we have flexible production capabilities to meet your needs.

Cost-Effectiveness: We optimize the design and manufacturing processes to provide cost-effective LED masks, helping you stay competitive in a fierce market.

Customer Service: We always prioritize customer-centric communication and support, ensuring your needs are met and providing the best solutions.

Whether you are looking for a new product development partner or wish to customize unique LED masks to meet market demands, FITTOP is your ideal choice. We look forward to collaborating with you to develop successful LED mask products and add new value and competitive advantages to your business.